Is Press-Fit the Future of Plumbing?

[vc_row][vc_column][vc_single_image image=”2324″ img_size=”large” alignment=”center”][vc_column_text]When doing plumbing work, connecting pipes is critical, and one of the most common activities. Securely connecting them plays a critical role in making a plumbing project successful, durable, and functional.

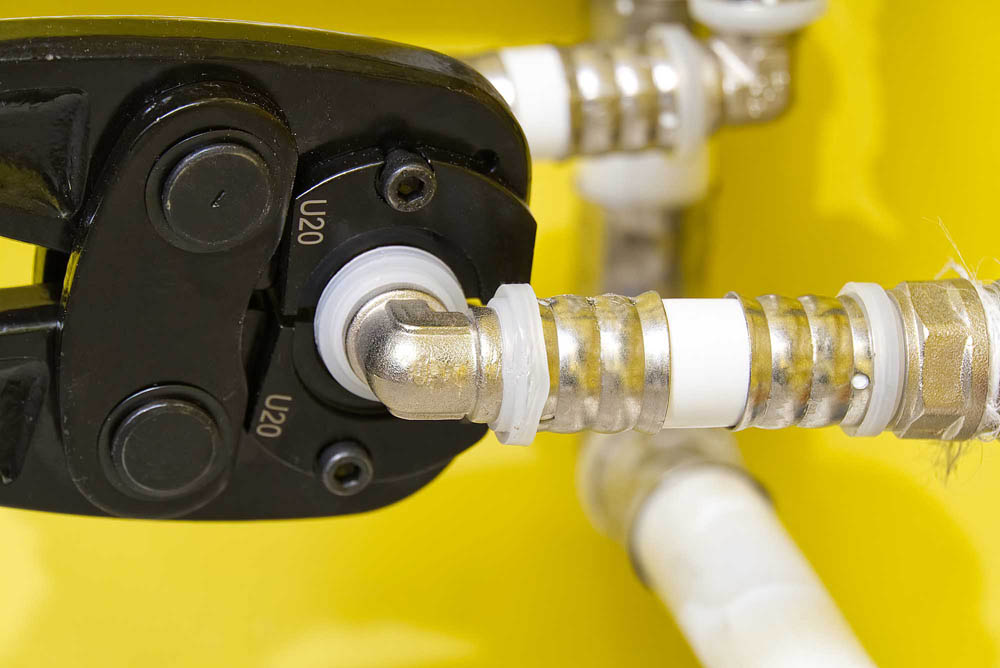

Traditionally, plumbers have relied on welding, soldering, and brazing to connect pipes and join other plumbing connections. These conventional methods are still widely used because they have been effective and functioning. However, there’s a better solution available in the form of press fittings. It is becoming a popular method to connect pipes.

For several reasons, press fittings make a better choice over conventional methods used to join pipes. Whether it’s plumbing projects, HVAC work, or commercial mechanical projects, press fittings provide excellent benefits.

But…is it possess the potential to be called the future of plumbing?

Let’s find out what makes it better than the conventional methods used in plumbing to connect pipes and create joints.

Benefits of Press Fittings over Other Methods

Here’re some amazing benefits of press fittings over various other methods you may need to know:

Press fittings save time

When connecting pipes with welding or soldering, it takes a significant amount of time. On the other hand, press fittings take a fraction of the time it takes to weld or solder. Ultimately, you can make connections in far less time than conventional methods. The speed of making connections with press fitting is its biggest benefit.

Press fittings save money

Welding, brazing, and soldering are complex skills and required immense training before a worker can finally make secure connections. In contrast, press-fitting doesn’t require as much training as conventional methods. A worker can learn to operate a press-fit tool in a short period. Training and hiring welders and soldering experts cost a considerable amount of money. When you use a press-fit tool, you don’t need to spend too much time and money on training workers — making it a cost-saving method.

Press Fitting Offers Secure Connections

You may get a press-fit tool of any brand depending on the operations you want or need. But one thing that remains consistent in all brands’ press-fit tools is the strength of the joints you get. When the pipe is prepared correctly as it must be, a press-fit tool provides a strong and secure connection.

The strength of the connection is as good as a welded or brazed connection. Some sophisticated hydraulic press tools come with an auto-cycle feature, which automatically shuts off upon creating the perfect connection — leaving you with no guesswork.

Press-fit provides better job site Safety

Jobsite safety and protection of the workers is always a priority Caution and safety. This is compromised when soldering, brazing or welding is performed on plumbing projects at a construction site as heat and flame are involved. In comparison, a press-fit tool doesn’t create any of them, bringing additional safety to the job site.

It significantly reduces the risk of on-site dangerous incidents and injuries. Operators controlling the press-fit tool aren’t required to wear as much safety gear as required when welding or soldering. It also decreases the cost.

Works on numerous materials

Regardless of the type of pipe system, you’re installing; press fittings are applicable on all. Its ability to connect copper, stainless steel, and carbon steel makes it a dynamic method.

Whether you’re working on a gas pipeline project or water pipeline project, you can use an appropriate press-fitting solution for the project.

Enable quick repairs

Unlike welding and soldering, press-fit doesn’t take much time to make repairs. It doesn’t matter if the pipeline is wet or dry, you can apply press fit on it. It makes the press-fit solutions ideal for both commercial, domestic, and industrial plumbing projects.

Because it can work on a wet pipeline, there’s no need to shut down the water supply to make the connection.

Uninterrupted maintenance

With press-fit, there’s no need to resume the operation on-site. Its ability to work on wet pipelines offers uninterrupted maintenance and smooth operations on-site. Moreover, it takes less time to repair connections, which means you’ll be dealing with far less downtime than when soldering or welding is used to make repairs.

Is It The Future Of Plumbing?

Considering its wide variety of applications, popular demand in the plumbing sector, and cost-effectiveness, it’s safe to say that it’s already a widely used method. If its use keeps increasing at the same pace in the plumbing industry, it will leave behind the conventional methods.

If you’re in the plumbing industry, own a plumbing firm, or a plumbing expert, it will pay off well if you learn press-fitting now. That’s because early adopters always get the biggest chunks of the benefits, competitive edge, and prepare for the future head-on. So get in touch with us now, and set an appointment for the customized services![/vc_column_text][/vc_column][/vc_row]